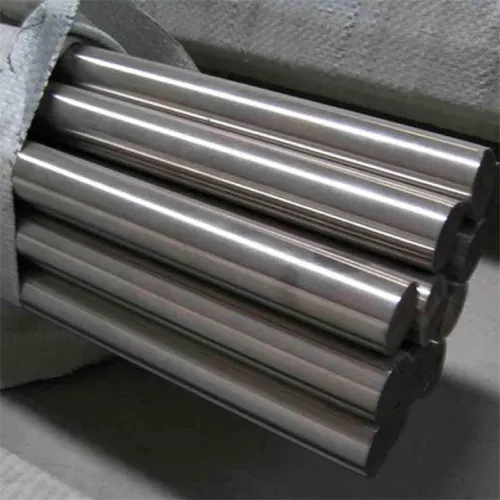

Composition and Characteristics

The enhanced performance of 347H stainless steel is a result of its carefully balanced chemical composition. The typical composition includes:

Chromium (Cr): 17-19%

Nickel (Ni): 9-13%

Carbon (C): 0.04-0.10%

Columbium/Niobium (Nb): 10xC to 1%

Manganese (Mn): 2% max

Silicon (Si): 1% max

Phosphorus (P): 0.045% max

Sulfur (S): 0.03% max

The addition of columbium (niobium) in 347H stainless steel enhances its stability by preventing the formation of chromium carbides, which can cause intergranular corrosion. The higher carbon content increases the alloy’s strength at elevated temperatures, making it more resistant to creep, a slow, permanent deformation that occurs under high stress and temperature.

Key Properties

347H stainless steel coil offers several key properties that make it an exceptional material for high-temperature and corrosive applications:

Superior High-Temperature Strength: The increased carbon content in 347H stainless steel significantly enhances its strength at elevated temperatures, making it ideal for applications that involve prolonged exposure to heat.

Excellent Creep Resistance: 347H stainless steel is specifically engineered to resist creep, a phenomenon where materials deform under long-term exposure to high temperatures and stress. This makes it suitable for demanding environments.

Enhanced Corrosion Resistance: The columbium stabilization prevents the formation of chromium carbides, ensuring that 347H stainless steel retains its corrosion resistance, even in welded structures or environments with repeated heating and cooling cycles.

Good Weldability: Despite its high carbon content, 347H stainless steel maintains good weldability, allowing for the fabrication of complex structures without sacrificing performance or durability.

Non-Magnetic in the Annealed Condition: Like other austenitic stainless steels, 347H is non-magnetic when annealed, which can be beneficial in specific applications where magnetism is a concern.

Applications of 347H Stainless Steel Coil

Due to its unique combination of high-temperature resistance, strength, and corrosion protection, 347H stainless steel coil is used in a variety of demanding applications across different industries:

Petrochemical Industry: 347H stainless steel is commonly used in the petrochemical industry for applications such as reactor vessels, piping systems, and heat exchangers, where materials must withstand high temperatures and corrosive environments.

Power Generation: The material is widely employed in power generation, particularly in superheater and reheater tubes, where its high-temperature strength and resistance to creep are essential.

Chemical Processing: 347H stainless steel is ideal for chemical processing equipment, including reactors, furnaces, and catalytic converters, where both high-temperature stability and corrosion resistance are required.

Aerospace Industry: The alloy’s ability to perform in high-temperature environments makes it suitable for certain aerospace applications, including exhaust manifolds and turbine components.

Heat Treatment Equipment: 347H stainless steel is used in the manufacturing of heat treatment equipment, such as furnaces and annealing boxes, where its resistance to oxidation and thermal stress is crucial.

Advantages of Choosing 347H Stainless Steel Coil

When selecting a material for high-temperature applications, 347H stainless steel coil offers several significant advantages:

High-Temperature Performance: 347H stainless steel is engineered to maintain its structural integrity and resist creep, even at extreme temperatures, ensuring long-term reliability in challenging environments.

Corrosion Resistance: The columbium stabilization prevents the formation of chromium carbides, which can cause intergranular corrosion, ensuring that 347H stainless steel retains its corrosion resistance, even after welding or thermal cycling.

Versatility Across Applications: The alloy’s ability to perform well in both high-temperature and corrosive environments makes it suitable for a wide range of industries, from petrochemical to power generation.

Durability and Longevity: The combination of strength, creep resistance, and corrosion resistance ensures that components made from 347H stainless steel have a long service life, reducing maintenance costs and downtime.

Conclusion

347H stainless steel coil is a high-performance material designed to excel in high-temperature and corrosive environments. Whether you are working on petrochemical equipment, power generation components, or chemical processing systems, 347H stainless steel offers the durability, strength, and resistance needed to ensure reliable performance under the most demanding conditions. Explore our range of 347H stainless steel coils today and find the perfect material for your high-temperature applications.