Stainless steel is a highly versatile, corrosion-resistant alloy used across industries, from construction and manufacturing to kitchenware and medical tools. Its popularity stems from its exceptional durability, strength, and ability to resist rust, making it essential in modern applications. But what makes stainless steel so unique, and how is it produced? This article explores its composition, types, manufacturing process, and benefits.

What Is Stainless Steel?

Stainless steel is a type of steel alloy primarily composed of iron and chromium. To qualify as stainless steel, the alloy must contain at least 10.5% chromium. Other elements like nickel, molybdenum, and carbon are often added to enhance its properties.

Key Properties

Corrosion Resistance: Chromium forms a protective layer of chromium oxide on the surface, preventing rust and oxidation.

High Strength and Durability: Resistant to wear and tear, making it suitable for heavy-duty applications.

Temperature Tolerance: Withstands high and low temperatures without deforming.

Low Maintenance: Easy to clean and maintain over time.

Aesthetic Appeal: Offers a sleek, polished appearance ideal for modern designs.

The ability to resist corrosion—owing to its chromium content—sets stainless steel apart from other metals. This thin, invisible oxide layer protects it, ensuring longevity in harsh conditions.

Key Types of Stainless Steel

Stainless steel is classified into four main types, each designed for specific uses:

Austenitic Stainless Steel

Contains high levels of chromium and nickel.Non-magnetic and highly resistant to corrosion.Common Uses: Kitchen utensils, food processing equipment, and architectural structures.

Ferritic Stainless Steel

Magnetic with lower carbon content, offering moderate corrosion resistance.Cost-effective but less durable than austenitic types.Common Uses: Automotive parts, appliances, and decorative trims.

Martensitic Stainless Steel

High in carbon, providing excellent strength and hardness.Offers moderate corrosion resistance.Common Uses: Surgical instruments, knives, and mechanical tools.

Duplex Stainless Steel

Combines properties of ferritic and austenitic stainless steel.High strength with superior corrosion resistance.Common Uses: Chemical plants, oil pipelines, and marine environments.

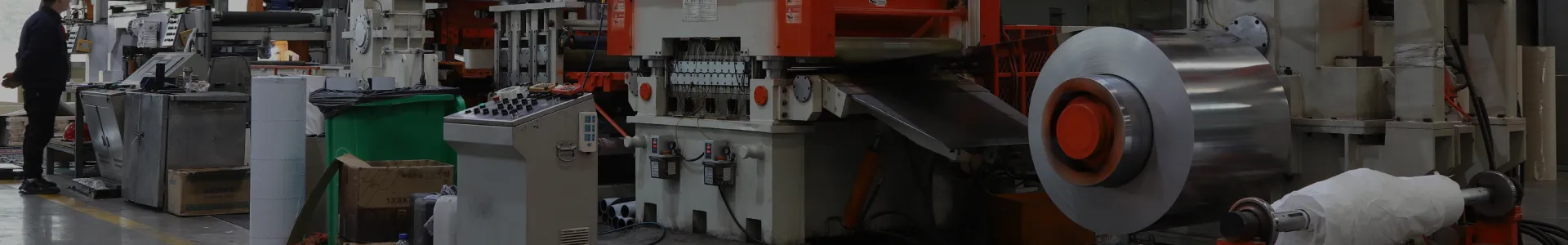

How Is Stainless Steel Made?

The production of stainless steel involves several carefully controlled stages:

Step 1: Gathering Raw Materials

Stainless steel begins with essential raw materials:

Iron Ore: The primary base element.Chromium: Provides corrosion resistance.Nickel: Improves strength and flexibility.Molybdenum: Increases resistance to acids and harsh chemicals.

Other elements like silicon, carbon, and manganese are added depending on the desired final properties.

Step 2: Melting and Refining

Raw materials are melted in an Electric Arc Furnace (EAF) at extremely high temperatures (over 1600°C).Once melted, the alloy is refined to remove impurities like sulfur or phosphorus.

Step 3: Casting

The molten stainless steel is cast into semi-finished forms, such as:

Slabs (for flat products like sheets and plates).Billets (for rods, bars, and wires).Ingots (large blocks for further processing).

Step 4: Forming

The cast stainless steel undergoes rolling to achieve the desired shape:

Hot Rolling: Heated and rolled into thicker products like sheets and plates.Cold Rolling: Rolled at room temperature to refine thickness and surface finish.

Step 5: Heat Treatment (Annealing)

Annealing involves heating the stainless steel and then cooling it gradually. This relieves internal stress, improves ductility, and enhances overall mechanical properties.

Step 6: Surface Finishing

To remove surface scales formed during heating, stainless steel undergoes:

Pickling: Acid treatment to clean and smooth the surface.Polishing: Achieves a shiny, mirror-like finish suitable for decorative or hygienic applications.

Step 7: Cutting and Shaping

Finally, the stainless steel is cut and shaped using techniques such as:

Shearing: Mechanical cutting with blades.Laser Cutting: Precise cutting for intricate designs.Machining: Using tools to achieve specific shapes and sizes.

Applications of Stainless Steel

Stainless steel is essential across various industries:

Construction: Used in buildings, bridges, and architectural facades for its durability and corrosion resistance.

Kitchenware: Sinks, cutlery, cookware, and food processing equipment due to its hygienic properties.

Medical Devices: Surgical tools, implants, and medical instruments thanks to its biocompatibility.

Automotive and Aerospace: Components like exhaust systems, frames, and aircraft parts for their strength and temperature resistance.

Industrial Applications: Pipes, storage tanks, and chemical equipment that handle corrosive substances.

Benefits of Stainless Steel

Exceptional Durability: Withstands wear, pressure, and heavy loads.

Corrosion Resistance: Performs well in moisture-rich or chemical-heavy environments.

Easy Maintenance: Requires minimal care and cleaning.

Recyclable: Environmentally friendly; stainless steel is 100% recyclable.

Aesthetic Appeal: Its sleek finish complements modern designs.

Stainless Steel vs. Other Metals

| Property | Stainless Steel | Carbon Steel | Aluminum |

| Corrosion Resistance | Excellent | Low | Moderate |

| Strength | High | Very High | Lower |

| Weight | Heavier | Heavier | Lightweight |

| Maintenance | Low | High | Moderate |

| Cost | Moderate | Low | Moderate |

FAQs About Stainless Steel

What makes stainless steel corrosion-resistant?

The protective chromium oxide layer prevents rust and oxidation.

Is stainless steel magnetic?

Ferritic stainless steels are magnetic, while austenitic types are not.

What are the main grades of stainless steel?

Common grades include 304 (general-purpose) and 316 (marine-grade).

Can stainless steel rust?

Rarely, but it may rust if the protective layer is damaged or exposed to extreme conditions.

Stainless steel is a remarkable material known for its corrosion resistance, strength, and versatility. From kitchen appliances to industrial equipment, its impact on our lives is undeniable. Its durability, recyclability, and modern appeal make it essential across industries.

Looking for more insights on stainless steel products? Explore our guides or contact us to learn more about their applications and benefits.

Reference:

HUYI STEEL:How Stainless Steel is Made: Four Processes

JIANGHEHAI IRON AND STEEL:Austenitic, Ferritic, Martensitic, Duplex, and Precipitation Hardening