Introduction:

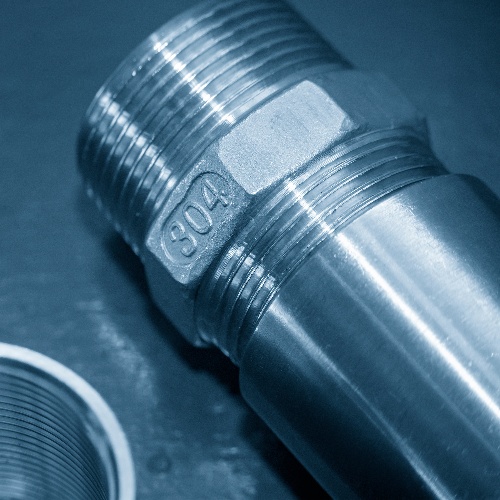

When it comes to selecting between 304 and 316 stainless steel, the decision can significantly impact the performance and longevity of your project. These two types of stainless steel are both popular due to their durability, but their differences can be critical depending on your needs. Let’s explore the pros and cons of each type and how to determine which is best for your specific application.

What Are the Disadvantages of 304/316 Stainless Steel?

While both 304 and 316 stainless steels are known for their corrosion resistance, neither is immune to certain types of degradation. Here are a few drawbacks for each:

Vulnerable to chloride-induced corrosion (e.g., from saltwater).

Prone to pitting in highly corrosive environments.

More expensive due to the added molybdenum.

Less readily available than 304 in some markets.

What Are the Weaknesses of 304/316 Stainless Steel?

304 Stainless Steel:

Lower resistance to corrosive elements like saltwater and industrial chemicals compared to 316.

Can suffer from stress corrosion cracking in extreme conditions.

316 Stainless Steel:

Slightly less formable and weldable than 304. especially in thicker sections.

Higher cost due to the molybdenum content, which may not always justify its use.

What Is the Main Difference Between 304 and 316?

The main difference between these two grades is the addition of molybdenum in 316 stainless steel. This additional element increases corrosion resistance, particularly against chlorides and industrial solvents. In environments where exposure to salt or chemicals is frequent, 316 provides a significant advantage in longevity. For general use or environments without high chemical exposure, 304 may suffice.

Key Chemical Composition:

304: 18% chromium, 8% nickel.

316: 16% chromium, 10% nickel, 2% molybdenum.

Why Is 316 More Expensive Than 304?

The higher cost of 316 is primarily due to the molybdenum content. Molybdenum is an expensive alloying element that significantly improves corrosion resistance, making 316 more suitable for harsh environments. As a result, industries dealing with marine environments or chemical exposure, such as offshore oil rigs or pharmaceutical production, often prefer 316 despite the price difference.

Stainless Steel Grade | Cost Comparison (approx.) |

304 Stainless Steel | 304 Stainless Steel |

304 Stainless Steel | 20-30% Higher |

How Can You Tell If It's 316 or 304?

Identifying whether you’re working with 304 or 316 stainless steel can be tricky just by looking at it, but there are a few methods:

Magnetic Test: Both 304 and 316 are austenitic and generally non-magnetic, but after fabrication, 304 may exhibit slight magnetism due to its structure.

Molybdenum Test Kit: You can use specialized kits that detect the presence of molybdenum, which is only present in 316.

Chemical Analysis: More expensive but definitive, sending a sample to a lab for precise chemical composition analysis can confirm the steel type.

Conclusion: 304 or 316—The Answer Depends on Your Application

Choosing between 304 and 316 stainless steel depends largely on the environment and specific needs of your project. If your application involves marine environments or industrial chemicals, 316’s enhanced corrosion resistance is likely worth the investment. On the other hand, for general-purpose use in a less corrosive environment, 304 offers excellent durability at a lower cost. Always consider the working conditions, budget, and long-term needs when making your decision.